Choosing custom wheels isn’t complicated to do on your own. Consider the following factors in this article to get better at choosing custom wheels.

Quick Tips for Choosing Custom Wheels

Adding a set of custom wheels can add a lot of visual appeal to just about any vehicle. We’ve put together some recommendations to help you choose the right wheels for your car or truck, including aesthetics, safety, size, fit, and tech compatibility.

1. Looking Good

The style and finish on a set of custom rims can dramatically change the look of your car, truck, or off-road vehicle. Start shopping right now or visit your local wheel shop. There, you can see specific sets of custom wheels on the make, model, year, and color of your vehicle. This is a great way to sift through the many options and narrow your choices before making a purchase decision.

2. Think Safety

Proper fit is crucial when choosing custom wheels. The pros at your local wheel store will help you look at three vital areas before choosing your set of wheels.

- Overall Diameter: The wheel and tire combination should always clear the braking components, suspension parts, and the body of the vehicle. This is important whether you want to increase the diameter of your wheels for a street-worthy look or decrease the wheel diameter for more tire sidewall and better off-road performance.

- Offset and Backspace: To ensure proper clearance, it’s critical to know how far inside and outside the entire wheel and tire package will sit in the wheel well. Improper backspace or offset can cause interference with things like the body and steering components and possibly decrease your turning radius. Learn more about offset and backspace.

- Proper Mounting: Many of today’s vehicles come from the factory with wheels that fit precisely around the hub. This is referred to as hub-centric fitment, which helps provide a consistent centering of the wheel and tire assembly when mounted to the vehicle. This reduces the chance of an imbalance that may result in a vibration in the steering wheel or seat while driving. Our team understands the importance of maintaining a hub-centric fit whenever aftermarket wheels are being considered.

3. Pick the Right Size

There are many sizes to consider when purchasing new wheels. The image below is an example of how plus and minus sizing works. Plus, sizing boosts the diameter of your wheels while decreasing the profile of the tire sidewall to match the overall tire diameter suggested by the manufacturer. Minus sizing works in the opposite way to allow for a taller sidewall. You can utilize the right sizing feature of Wheels Visualizer to ensure you have the proper fit.

4. Bolt-Pattern Matters

There are a variety of bolt patterns and your new custom wheels must match in order to fit your vehicle properly. Even if your vehicle has five lugs, there’s no guarantee that every five-hole wheel will fit.

5. Check the Tech

TPMS (Tire Pressure Monitoring System) compatibility is also important. Equipped in most new vehicles, the TPMS in your vehicle should be reset after installing new wheels.

What To Consider When Choosing Custom Wheels?

1. Custom Wheels: Size and width

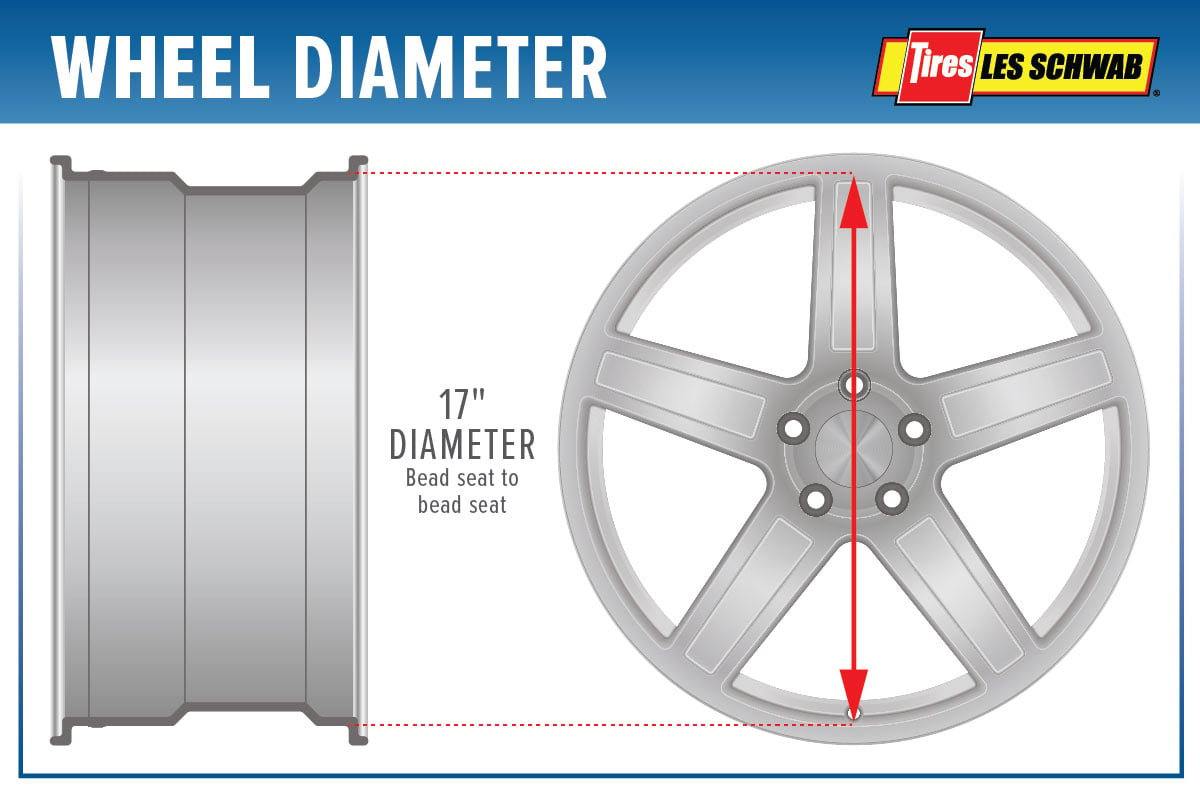

When choosing custom wheels, size and width considerations should be taken into account. The rim size, or wheel diameter, is the most common descriptor and it is measured across the inner bead seating area. Factory sizes for wheels can range from 16″ to 22″.

If you choose a wheel that is larger than the factory wheel diameter, it is called plus-sizing. The larger the diameter of the wheel, the heavier it can get. Steel wheels should not be larger than 16″ in diameter as they become too heavy for practical use and handling. Lightweight alloy wheels up to 20″ in diameter are recommended for everyday driving, and high-performance cars should use even lighter weight forged wheels when the diameter reaches 18″ for safe handling.

In addition to size, the width of the wheels should also be taken into account. It is important to make sure the wheels you choose fit the make, model, year, and color of your vehicle.

2. Custom Wheels: Offset and backspacing

When choosing custom wheels, it is important to consider both the offset and backspacing of the wheels. The offset of a wheel determines how far in or out the wheel sits in relation to the hub and the guard/wheel arch, and the backspacing is the measurement from the back of the mounting surface to the inner wheel lip.

When upgrading from factory OEM wheels, it is essential that the new wheels feature the same bolt circle measurement and center bore size as the original wheels, in order for them to fit properly. Adding positive offset will tuck the rim further into the wheel well, and adding a negative offset will make the wheels jut out further from the wheel lip. This is beneficial for wider tires that require more clearance from the inner fender well.

If the backspacing is too large, the wheel and tire assembly can rub on the inner fender liner and suspension components, while too small of a center bore won’t allow the wheel to fit snug against the hub face. It is therefore important to carefully consider the offset and backspacing when choosing custom wheels in order to ensure that they are the right fit and that they will not interfere with the car’s performance.

3. Custom Wheels: Hub design

When it comes to choosing custom wheels for your car or truck, there are a few factors to consider when selecting a hub design. The type of wheel, the size, and the finish are all important elements to consider when making your selection. Aluminum alloy wheels are typically lighter and stronger, making them a popular choice for performance and handling, as well as improved gas mileage. Steel wheels are heavier but more durable and offer more stability, making them ideal for off-road or heavy-duty work. The finish you choose for your wheels can also have a big impact on their overall look, with common finishes including polished, painted, powder-coated, and chrome-plated.

No matter what type of wheel you choose, make sure to talk to experts to ensure you are getting the right wheel for your tire-wheel assembly and vehicle. Proper installation is also key to getting the most out of your custom wheels, so make sure to have a professional technician properly install and align your wheels. With the right wheels, your car or truck will look great, perform even better, and provide a sense of customization that is unique to you.

4. Custom Wheels: Rim material

When selecting the perfect custom wheel rims, it is important to consider both the material and the finish. Aluminum alloy wheels are lightweight and strong, making them ideal for improving performance, handling, and gas mileage. Chrome wheels are coated in chrome, reducing the chance of oxidation and improving the look of the wheel.

Finally, custom steel wheels are heavier than aluminum and are perfect for off-road driving and heavy-duty work, providing more stability and durability. Each material provides its own unique benefits, so it is important to consider the demands of your vehicle, your budget, and your personal preferences in order to make the right choice.

5. Custom Wheels: Bolt pattern

When choosing custom wheels, one of the most important bolt patterns to consider is the number of lug holes in the rim. Common options include 4-lug, 5-lug, 6-lug, and 8-lug bolt patterns. The distance between the holes is also important, as there are variances in the distance between rims with the same number of lug holes. This measurement can be in millimeters or inches, and it is the diameter of the imaginary circle that the wheel studs create.

Additionally, you will need to make sure the wheel you choose matches your car’s existing wheel studs and hub-centric fitment for proper centering of the wheel and tire assembly when mounted to the vehicle. With the right bolt pattern, you can ensure the wheel looks great and meets safety requirements.

6. Custom Wheels: Sizes available

Custom wheels come in a variety of sizes, from 12″ to 24″, and sometimes beyond. The most common size descriptor is the wheel diameter, which measures the inner bead seat area – not edge to edge. A larger wheel diameter is referred to as plus-sizing and can maintain a lower profile tire with the same overall wheel height. When choosing a wheel size, it’s important to make sure it fits both your brakes and wheel well for a safe and proper installation.

7. Custom Wheels: Price and budget

When choosing custom wheels, price and budget are important considerations. Generally speaking, the bigger the wheels, the more you will have to compromise in terms of durability and drivability, which can drive up the cost. On the other hand, advancements in materials and engineering can improve the results you can achieve for any given combination of specs, giving you the opportunity to balance performance and price.

Tire selection also affects the overall cost of custom wheels. Brand name tires such as Nokian, Goodyear, Hankook, Falken, and Michelin tend to be more expensive, but offer higher quality performance. At The Tire Works, you can choose from a wide selection of wheel sizes, styles, and brands for passenger cars, trucks, and SUVs. If the custom wheels you want aren’t in our current inventory, we can special order upon request.

At Carlson’s Tire Pros & Auto Care, you have access to all the leading brand’s custom wheels and the team will help you find the best options for your vehicle within your budget. We are committed to providing our customers with the best possible deal paired with the best service.

In the end, choosing the right custom wheels is a matter of personal preference and budget. With so many options to choose from, it helps to work with professionals who understand the product and the needs of the customer.

8. Custom Wheels: Wheel fitment

When choosing a custom wheel based on wheel fit, there are several factors that should be taken into account. The overall diameter is important, as the wheel and tire combination must clear the braking components, suspension parts, and the body of the vehicle. Offset and backspace are also important, as they determine how far inside and outside the entire wheel and tire package will sit in the wheel well. Improper backspace or offset can cause interference with the body and steering components, and possibly reduce the turning radius.

Finally, proper mounting is necessary to provide a consistent centering of the wheel and tire assembly when mounted to the vehicle, which reduces the chance of an imbalance that may result in a vibration in the steering wheel or seat while driving. It is important to maintain a hub-centric fit when considering aftermarket wheels.

9. Custom Wheels: Wheel adapters

Wheel adapters are devices used to mount custom wheels on cars and trucks that have a different bolt-pattern than the wheels. They come in many different types, ranging from standard four or five-lug adapters to high-performance adapters and spacers. In order to choose the right wheel adapter for your vehicle, there are a few things to consider.

The first is the size of the adapter. Standard adapters are typically 4 or 5 lugs, while many performance-oriented vehicles require 8 or 10 lugs. The lugs are the bolts that hold the wheel in place and the number and size can vary, so it is important to confirm the bolt pattern of your vehicle and the wheel to ensure compatibility.

The second factor to consider is the type of adapter. Standard adapters are usually made of steel and are designed to fit the standard lug bolt pattern, while performance adapters are often made of aluminum and designed to fit a variety of different bolt patterns. Performance adapters are also designed to provide additional clearance for larger wheels and tires, while standard adapters are designed to be a more universal fit.

Finally, it is important to consider the size and offset of the adapter. Offset is the distance between the wheel’s mounting surface and the centerline of the wheel, and it is important to make sure the offset of the adapter is compatible with the offset of the wheel. The size of the adapter should also be similar to the size of the wheel, so that it provides a secure and reliable fit.

Ultimately, choosing the right wheel adapter for your custom wheels depends on the size and bolt pattern of your wheels and vehicle, as well as the type and offset of the adapter. With the right adapter, you can safely mount your custom wheels and enjoy improved performance and a more personalized look.

10. Custom Wheels: Wheel stationary

When it comes to choosing a stationary wheel for custom wheels, there are a few things to consider. First, you’ll want to decide between steel and aluminum alloy wheels. Aluminum alloy wheels are light-weight and strong, improving performance, handling, and gas mileage. Steel wheels are heavier and are best for off-road driving and heavy-duty work, as they provide better stability. You’ll also want to think about the finish of your custom wheels. Depending on your needs, you can choose from a polished, painted, powder-coated, or chrome plated finish.

When selecting your custom wheels, you’ll also want to consider the bolt pattern, offset, and wheel size. Bolt patterns are the number of lug nuts that attach the wheel to the car and are usually either four, five, or six. The offset is the distance from the center line of the wheel to the mounting surface and affects the way the wheel contacts the road. Wheel size will affect the tire size and diameter, as well as the overall look of your vehicle.

Finally, you’ll want to consider the cost and installation of your custom wheels. At all of our Tire Works locations, we offer a wide selection of wheel sizes, styles, and brands, and if we don’t currently have the custom wheels you want, we can special order them. Our expert technicians can properly install them and ensure they are aligned and balanced.

11. Custom Wheels: Lubrication

When selecting custom wheels for your vehicle, it is important to consider the type of lubrication that is best suited for your wheels. The two main types of lubrication are oil-based and non-oil-based lubricants.

Oil-based lubricants are designed to prevent corrosion and provide a long-lasting barrier of protection on the wheels, while non-oil-based lubricants are designed to provide a quick and easy lubrication, but do not offer as much protection over a longer period of time.

Oil-based lubricants are typically used on chrome-plated alloy wheels, since they provide a long-term barrier against corrosion and provide a better finish. Non-oil-based lubricants, however, are better suited for wheels made from aluminum or other metals, since they provide a quick and easy application, but do not offer the same level of protection against corrosion as oil-based lubricants.

In addition, it is important to use a soft, non-abrasive cream wax after cleaning the wheels with mild dish soap and water in order to further protect the finish of the wheels.

When choosing custom wheels for your vehicle, it is important to consider the type of lubrication that best suits your needs and the type of wheels you are installing. Oil-based lubricants are ideal for chrome-plated alloy wheels, while non-oil-based lubricants are better suited for aluminum and other metal wheels. Furthermore, regular cleaning and waxing will help maintain the finish of your wheels and provide additional protection against corrosion.

12. Custom Wheels: Weight and balance

When it comes to choosing custom wheels, weight and balance are two essential factors to consider. Alloy wheels are a popular choice because they are lightweight and strong, making them ideal for improving performance and handling. They come in a variety of finishes and can be up to 20” in diameter. Steel wheels, on the other hand, are heavier and less suitable for everyday driving, but are great for off-road vehicles and larger tires. Steel wheels should generally not exceed 16″ in diameter. For high-performance vehicles, forged wheels should be used when the diameter reaches 18” to ensure safe handling.

It is important to consider your overall goal when selecting new custom wheels and take into account the type of vehicle you have. Lightweight alloy wheels will provide the best performance and handling, while steel wheels are more suited for off-road vehicles. Forged wheels are the best choice for high-performance vehicles. At Carlson’s Tire Pros & Auto Care, our focus is on your complete satisfaction and we can provide you with the perfect custom wheels and tires to meet your needs.

13. Custom Wheels: Steering response

When evaluating the steering response of custom wheels, there are several important factors to consider. First, the width of the rim should be taken into account. If it is wider than stock, there may not be enough clearance for the ball joint or steering arm, resulting in a potential for the wheel to rub against the fender. Additionally, any significant size changes can cause steering geometry to be affected and can lead to overstressed wheel bearings.

Secondly, the type of wheel chosen is important and should be based on the vehicle, its dimensions, and its use. For example, off-road wheels may need to be larger than those used for street driving, while spinning rims may be more suited for cruising around town. Lastly, the ratio of the rim to tire should be taken into account, as this will determine the impact of the new wheels on the odometer and speedometer, as well as their effect on steering and stability.

It is important to weigh all these factors when considering custom wheels for a vehicle in order to ensure the best possible performance and look.

14. Custom Wheels: Cornering

Choosing the right custom wheel for cornering is an important decision. It is important to consider the wheel size, type of wheel material, wheel finish, and wheel design.

Size is a major consideration when selecting custom wheels for cornering. The wheel size affects the vehicle’s performance and stability. It is important to choose the right wheel size for your cornering needs. Larger wheels provide better handling and stability while smaller wheels provide better acceleration.

The type of wheel material should also be taken into consideration when selecting custom wheels for cornering. Aluminum wheels are lightweight and provide better performance while steel wheels are heavier but more affordable.

The wheel finish also plays an important role in the performance of the wheel. Different wheel finishes such as chrome, black, and powder coated can provide unique looks and improved performance for cornering.

Finally, wheel design should also be taken into account when selecting custom wheels for cornering. Different wheel designs can provide different levels of grip, balance, and stability. It is important to select the wheel design that best suits your cornering needs.

In conclusion, size, type of wheel material, wheel finish, and wheel design are all important factors to consider when choosing a custom wheel for cornering. By taking these factors into account, you can make sure you select the perfect custom wheels for your cornering needs.

15. Custom Wheels: Tire and rim package

Choosing the right tire and rim package for custom wheels is a big decision. There are various factors that need to be taken into consideration before making a purchase. Aesthetics, safety, size, fit, and tech compatibility play a role in the selection process.

Aesthetics are an important factor when it comes to custom wheels. The style and finish of the wheel can make a huge difference in the overall look of your vehicle. You can shop online or visit a wheel discovery center to see the different wheel options on your exact make, model, year, and color of your vehicle.

Safety is also an important factor when considering custom wheels. The right wheel size and weight can make your vehicle handle better and increase its overall performance. When selecting the wheel size for your vehicle, it is important to take into account the terrain and driving conditions.

The wheel fit is also important when choosing a tire and rim package for custom wheels. Make sure to select a wheel and tire size that is compatible with your vehicle. It is also important to consider the bolt pattern and the offset when selecting a wheel for your custom wheels package.

Lastly, you should consider the tech compatibility of your wheels. Make sure the wheel and tire combination is compatible with the suspension and wheel bearing components on your vehicle.

Choosing the right wheel and tire package for your vehicle requires research, and speaking with a professional is highly recommended.

16. Custom Wheels: Tyre information panel

The information panel on tyres can have a significant effect on the choice of custom wheels. The type of tyre you choose, such as Nokian, Goodyear, Hankook, Falken, and Michelin, will influence the size, performance and overall look of your vehicle. For example, if you choose a tyre with a low profile, it will usually require a larger, wider wheel to fit, while a higher profile tyre will fit a smaller wheel. Additionally, if you want to improve your vehicle’s performance, you may choose a tyre with a higher speed rating, which will require a larger wheel to support it.

Lastly, if you want to customize your vehicle’s look, a higher quality wheel can help create a more distinctive style and make your vehicle stand out in a crowd. Ultimately, the information panel on tyres is an important factor to consider when selecting the perfect set of custom wheels.

17. Custom Wheels: Rim and wheel center

When choosing a custom wheel rim and center, there are several factors to consider. Firstly, the wheel needs to fit the centering hub properly, so check for compatibility with spacers or different wheels if necessary. Secondly, the offset of the wheel needs to be correct, as this will determine whether it can clear the brakes and suspension.

It is also important to distinguish between wheels and rims; the rim is the outer edge of the wheel where the tire bead sits, while the wheel is made up of the rim, and the disc which is where the bolt pattern is found. Custom wheels are often referred to as custom rims, but this is incorrect terminology.

Finally, when it comes to maintenance and care, different wheel finishes require different levels of care. Chrome-plated aluminum alloy wheels should be cleaned with mild dish soap, dried with a clean soft cloth, and then coated with a wheel seal or soft non-abrasive cream wax. Clear-coated wheels should be cleaned with mild dish soap and water, while powder-coated and PVD rims should be cleaned with mild dish soap and water, followed by drying with a clean soft cloth.

Polished aluminum alloy wheels should also be cleaned with mild dish soap and water, and then drying with a clean soft cloth, and applying a soft non-abrasive cream wax or wheel seal. Chrome-plated steel wheels should be cleaned to prevent rust, using mild dish soap and water, and then drying with a clean soft cloth.

18. Custom Wheels: Road imperfections

When choosing custom wheels for your vehicle, it is important to consider the impact that road imperfections can have on the rims. Stock wheels are generally designed to handle everyday road conditions, but custom rims will require extra consideration.

On the one hand, a bigger rim size can provide greater aesthetic appeal, but it can also compromise durability and drivability due to weaker materials and engineering. On the other hand, smaller rims are often more durable and offer improved handling, but may not have the same visual impact. It’s important to consider the environment you’ll be driving in and the type of road conditions you may encounter.

Additionally, if you’re planning to use the vehicle for off-roading, you may need to choose a larger rim size to ensure your safety and performance. Ultimately, the best custom wheels for your vehicle will depend on your personal preferences and needs.

19. Custom Wheels: Terrain use

When choosing custom wheels for terrain use, there are several factors to consider. First, consider the type of terrain you’ll be driving on, as this will determine the size of the wheels you need. Larger wheels are perfect for use in the mud and can help you get out of a variety of difficult situations. If you’ll be mostly driving on the road, choosing an alloy wheel could be a wise decision for managing weight while improving performance.

Second, the material of the wheel is important. While aluminum wheels are generally lighter than steel, steel wheels are heavier and more resilient, making them better suited for off-road driving and heavy-duty work. Steel wheels are also available in a variety of finish options such as polished, painted, powder-coated, or chrome plated.

Finally, the look of your wheels is important. You can easily customize your vehicle with a style that matches the look you’re going for. There are a variety of brands available on the market today, ranging from Cragar, Pacer, Motiv Wheels, and Focal to name a few.

No matter your needs, custom wheels can be a great way to improve your vehicle’s terrain capabilities and customize its look. It’s important to consider the type of terrain you’ll be driving on, the material of the wheel, and the look you’re going for when selecting a custom wheel for your vehicle.

20. Custom Wheels: Lug mounting

Custom wheels are a perfect way to personalize your vehicle and give it a unique look. One option for mounting your custom wheels is lug mounting, which is where the wheel is fastened to the hub using specialized equipment and mounted using lugs. This method of mounting wheels is popular due to its affordability and ease of installation.

The primary advantage of lug mounting is that it is a relatively quick and easy process. All that is required is a socket wrench or torque wrench and the proper lug nuts for the specific wheel. Additionally, lug mounting allows for a greater degree of customization in terms of wheel size and offset.

However, there are also some drawbacks to lug mounting. For example, lug mounting does not provide the same level of security as other mounting methods such as bolt-on or welded-on mounting. Additionally, lug mounting is not as precise as other mounting methods and is more likely to lead to misalignment. Furthermore, lug mounting can be more time consuming than other mounting methods in terms of installation.

In conclusion, lug mounting is a cost-effective and straightforward way to mount custom wheels. However, it is important to consider the potential drawbacks of lug mounting before making a decision.

Get Custom Wheels with Wheels Visualizer

Remember that your options will be specific to the make and model of what you drive. Talk to a tire expert at your local shop to make sure you’ll get the right custom wheels that will fit your vehicle and meet your performance expectations.

If you are a custom wheel & tire shop, customizer, or dealership and want to explore opportunities in Wheels Visualizer for your business, contact Susan (318) 294-9355 or Harold (469) 536-8478, or get started today.